The range ranges from manual insertion of the package in a corner welder to fully automatic welding and shrinking of the film around the package. POF (polyolefin), PP (polypropylene) and PVC (polyvinyl chloride) as well as PE (polyethylene) film can be processed. Welding time, temperature and shrink time are adjustable for a perfect result.

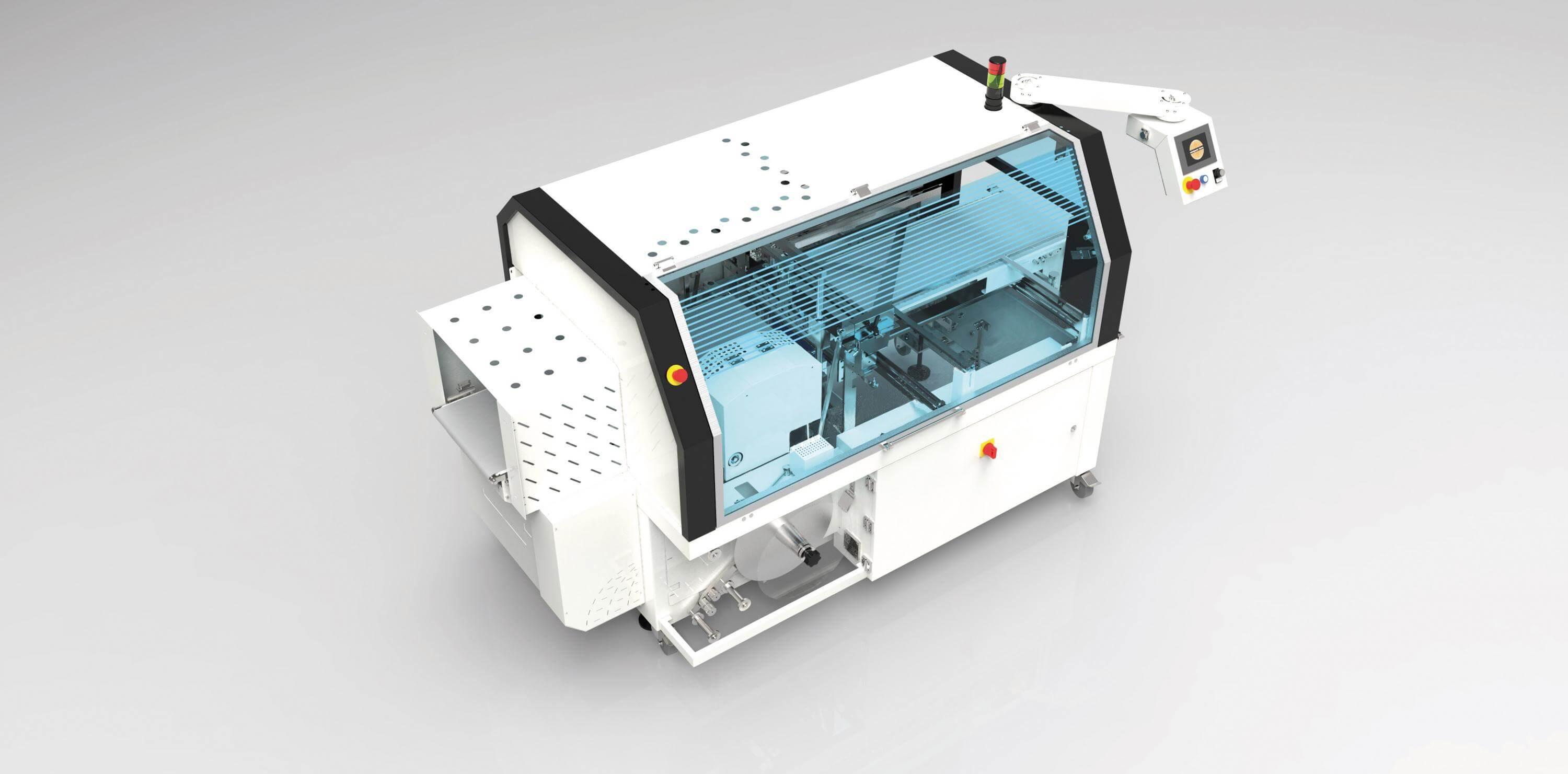

In dome machines, the welding and shrinking of the film takes place simultaneously under a transparent dome.